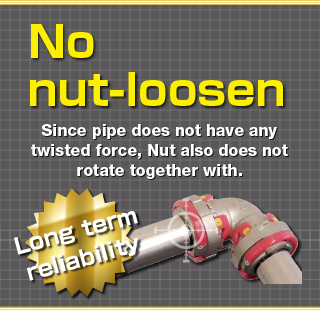

Nut of KK Best does not rotate together with pipe

Nut does not loosen due to vibration

Nut also does not loosen due to earthquake shaking

Tensile strength : Su pipe expanded area < Nut

Structure and Specification

About strength

Lock Ring mechanism for secure strength.

Resistance to detachment

We are evaluating its resistance to detachment during pre-insulation and insulation work to ensure it does not come off easily.

(We have confirmed no detachment due to vibration or pulsation by conducting vibration tests and repeated internal pressure tests.)

Rotational torque resistance

While the fitting is designed to have minimal rotational torque on the pipe, we evaluate its torque resistance performance to account for unexpected events.

Condition during maximum torque

Overriding of claw section between the main body and the nut.

After overriding, the lock ring becomes non-detachable and non-reusable, but it does not affect the basic performance (no leak, no pull-out) of the fitting.

Long term liability

Nylon(PA66)

Engineering plastics with excellent heat resistance, impact resistance, wear resistance, and chemical resistance.

A well-balanced material used in a wide range of applications, from automobiles to clothing and fishing lines.

Tested for chemical resistance (Thread sealant, PVC adhesive, plasticizer)

Tested for chemical resistance (Thread sealant, PVC adhesive, plasticizer) Undergoing weather resistance testing (Metal halide lamp model)

Undergoing weather resistance testing (Metal halide lamp model)

Non-reusable

Designed not to be removed without destruction.

Waterproofing with long-term reliability using O-rings

Feature and Structure

Water entering from gaps of the pipe is sealed by O-rings.

By placing a double layer protective ring with heat-resistant polyethylene on the water-contact side of the O-ring, we enhance safety and durability.

-

Proven Performance

This structure has a track record of approximately 7 years, and it has been confirmed that there is no degradation or deterioration.1 -

Compression Test

It has been confirmed through comparative performance tests with conventional products, such as compression endurance tests in chlorine water.2 -

Degradation Test

No problem found in the accelerated degradation test using the actual SAS322.3 -

Water Flow Test

In our proprietary flow test using high-temperature and high-chlorine water, there were no problems with a test equivalent to 40 years of use.4