Performance Test

| Test ParameterChart A | ||||

|---|---|---|---|---|

| No | Test Name | Test Method | ISO Standard | JCDA Standard |

| ① | Gas Tightness Test | Helium gas pressure of 4.3 MPa shall be applied before and after each test as specified by the ISO standard to confirm that the leakage rate after 5 minutes is below 7.5x10-7 Pa·m3/s. | ○ | - |

| ② | After each test specified by the CDA standard, nitrogen gas pressure of 4.3 MPa shall be applied and held for 5 minutes to confirm the absence of leaks or any other abnormalities. | - | ○ | |

| ③ | PTV Test (Pressure, Temperature, and Vibration) | 1) PT Test n1: Convert -45°C x atmospheric pressure ⇔ 140°C x nitrogen gas pressure 4.3 MPa for 50 cycles. 2) PT Test n2 : Perform 200 cycles of atmospheric pressure ⇔ nitrogen gas pressure of 4.3 MPa at 140°C ambient temperature. 3) V Test n3 : Perform 2 million cycles at a specified displacement x and frequency. |

○ | - |

| ④ | Freeze Test | After subjecting the test specimen in water to a vacuum of -500 mbar for at least 10 minutes, perform 30 cycles of freezing at -15°C for 30 minutes ⇔ thawing in water for 5 minutes. | ○ | - |

| ⑤ | Internal Pressure Test | Apply a water pressure of five times the maximum operating pressure (21.5 MPa) and hold it for one minute. | ○ | - |

| ⑥ | Refrigerant Compatibility Test | Immerse O-rings and V-packings in a liquid refrigerant and refrigeration oil mixture (5wt%) and hold them at 50°C for 14 days. Afterward, visually inspect to confirm the absence of any abnormalities such as swelling or tearing. Two types of liquid refrigerants, R410A and R32, are used. |

○ | - |

| ⑦ | Vacuum Test | Evacuate the test specimen to a vacuum pressure of 6.5 kPa (absolute) or lower, and confirm that the pressure rise after 1 hour is less than 0.2 kPa. | ○ | - |

| ⑧ | Fatigue Test | Apply atmospheric pressure ⇔ water pressure of 4.3 MPa to the test specimen at a rate of 20 to 60 cycles per minute for 250,000 cycles. Maintain atmospheric pressure and 4.3 MPa for each duration of at least 0.1 seconds. |

○ | - |

| ⑨ | Tension Test | Apply the specified load to the test specimen for each size. | - | ○ |

| ⑩ | Max. Bending Test | Using a tensile testing machine, bend the pipe at a span of 1,000mm and a bending speed of at least 10mm/min until it reaches a bending angle of 15° or the pipe undergoes plastic deformation. | - | ○ |

| ⑪ | Repeated Bending Test | Apply 10 cycles of 10mm displacement in the upward and downward directions at a span of 1,000mm and a speed of 10mm/min or higher. | - | ○ |

| Test ParameterChart B | |||

|---|---|---|---|

| № | Test Name | Standard | Test Parameter |

| ⑫ | Saltwater Spray Test | Company Standard | After conducting a saltwater spray test under the following conditions, perform an air tightness test to confirm there is no leakage.(Salt water spray test) Saltwater concentration of 5%, spray duration of 360 hours (15 days), and temperature environment at 35°C. |

| ⑬ | Vibration Resistance Test | Company Standard | Perform the vibration test with a pipe length of 500mm and air pressure applied at 0.5MPa. Afterward, confirm that there is no loosening or leakage of nuts.(Vibration conditions) Amplitude of 2.5 mm at 10 Hz for 1 million cycles. |

| ⑭ | Torque Tightening Test | Company Standard | Using a digital torque wrench, verify the tightening torque of the nuts. |

| ⑮ | Stress Corrosion Cracking Test | Company Standard | Verify that the fittings over-tightened with torque 1.5 times the standard installation torque do not exhibit harmful cracks in an ammonia atmosphere. |

- Tension Test

Apply a tensile load equal to or greater than the loads shown in the table below to the test specimen, with pipes connected to both ends of the fitting, using a tensile testing machine.

Apply a tensile load equal to or greater than the loads shown in the table below to the test specimen, with pipes connected to both ends of the fitting, using a tensile testing machine.

After conducting the tensile test, perform an air tightness test on the test specimen and confirm its compliance with the specifications.

- Torque Tightening Test

Using a digital torque wrench, verify the tightening torque of the nuts.

Using a digital torque wrench, verify the tightening torque of the nuts.

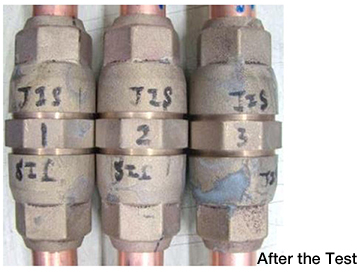

- Stress Corrosion Cracking Test

Verify that there are no harmful cracks in the fitting when used in an ammonia atmosphere. At 1.5 times the tightening torque test conditions, no harmful cracks occur.

Verify that there are no harmful cracks in the fitting when used in an ammonia atmosphere. At 1.5 times the tightening torque test conditions, no harmful cracks occur.