FEATURE

1

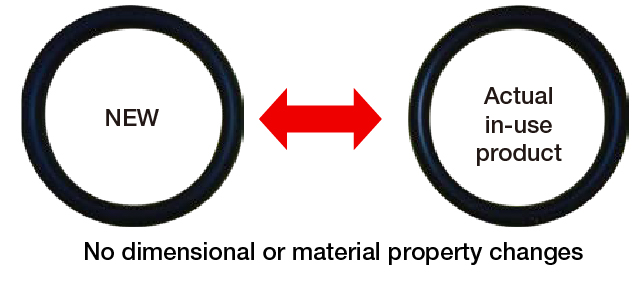

Using ternary fluorine rubber

Inadequate water quality does not affect the O-ring.

Even in situations where the water quality is inadequate and stainless pipes undergo corrosion, no degradation is observed in the O-ring.

(Note: The applicable water quality falls within the conditions specified in the catalog, etc.)

Ternary fluorine rubber has high-performance

The adopted ternary fluorine rubber is approximately 10 times more expensive than general-purpose O-ring materials, but its quality, durability, and adoption track record are sufficient. Please use it with confidence.

No trouble in 10 years of use

A track record of trouble-free performance in 10 years of use.

2

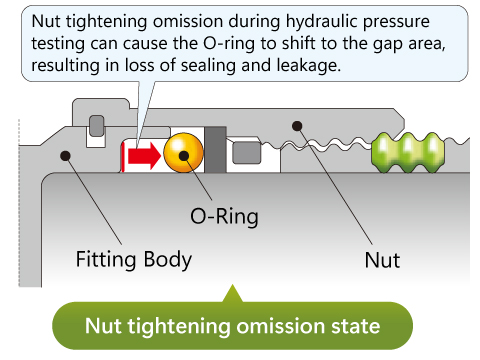

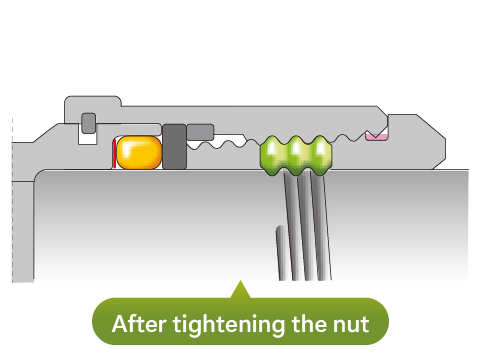

Nut tightening omission can be detected with 100% accuracy during hydraulic pressure testing

It is the only fitting that can be detected during hydraulic pressure testing, even when the pipes are fixed (e.g., vertical pipe with U-bolt restraints).

● Certainly find abnormalities

3

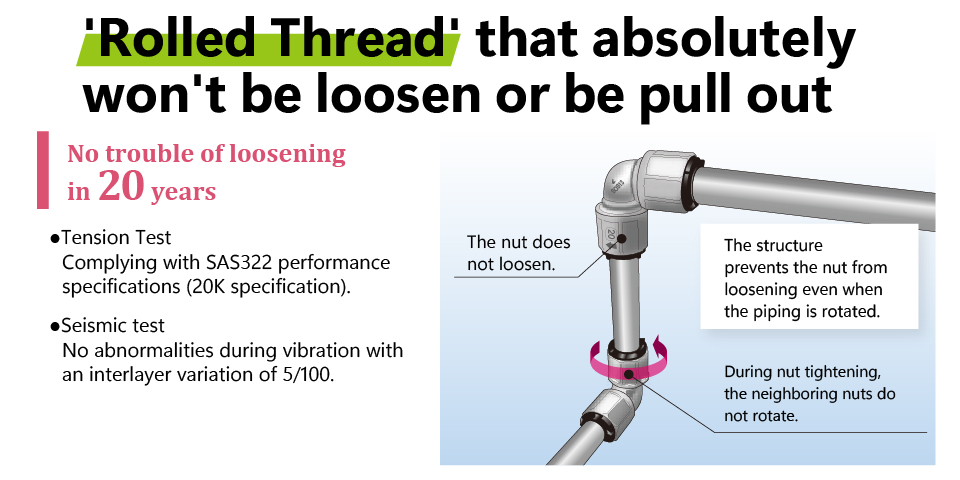

The nut doesn't loosen or rotate together

Securing the nut and the body with C-ring

Piping rotation test

Seismic test

Soroban Method

4

Recommendation for renovation projects

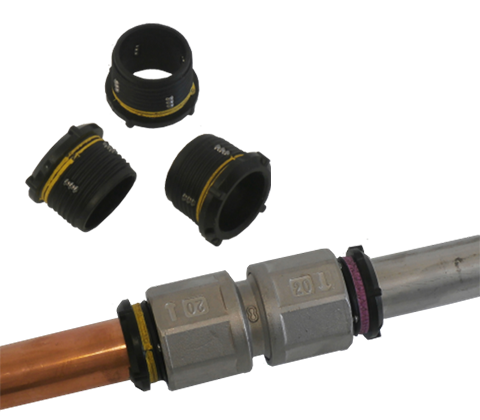

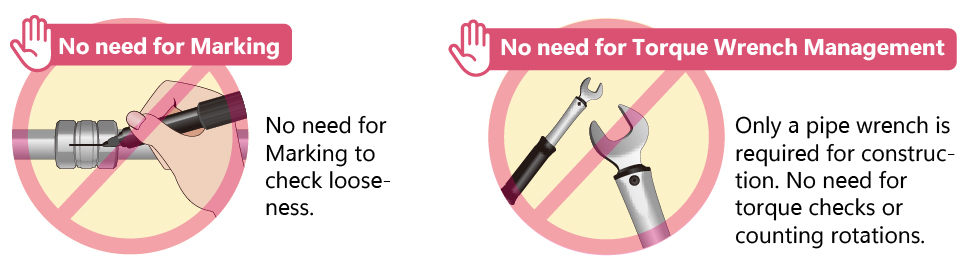

Minimum tool and equipment required for installation

Only a pipe wrench is required for connection work and heavy tools and machinery are not necessary.

Roller cutter can be used (no chips are produced)

Roller cutters are ideal for cutting pipes during expansion or replacement work from existing pipes in ceiling spaces or pits.

5

Minimum number of tools and equipment required for installation

The copper pipe retainer has a yellow indicator.

The copper pipe retainer is utilized for 1,000 units per month and is used for fire-free connections with copper pipes.